Mixers are used to make a homogeneous mixture of all paint materials. This is especially important in the making of varnishes and water-based paints. There are a variety of industrial mixers available. Selecting a suitable mixer will depend upon the material it interacts with. The general components of all mixers include a vertical mixing tank, one or more impellers, electric motor, and vertical baffles. The impeller mixes the material it consists of a shaft with one or more impellers. This component is where the differentiation of mixers occurs. Impellers are split into two categories axial and radial. Axial impellers are the most commonly used throughout the paint industry.

Below is a list of mixers used in the paint manufacturing industry.

Below is a list of mixers used in the paint manufacturing industry.

- Manual Mixers

- Automatic Mixers

- Kneaders

- Colloid Mills

- Rotary Churns

- Air Stream Mixers

Mills

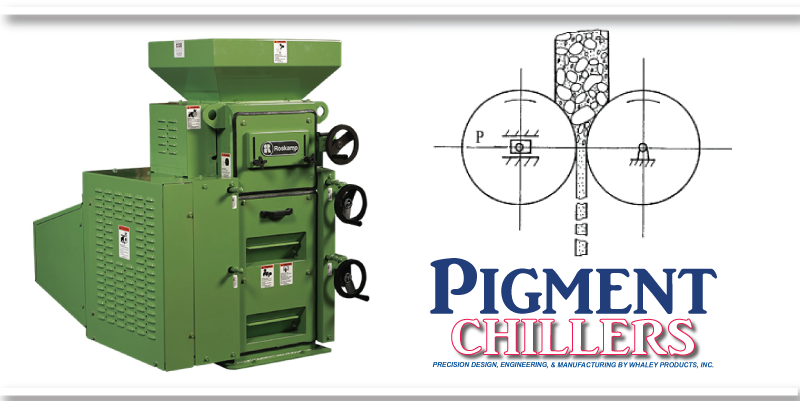

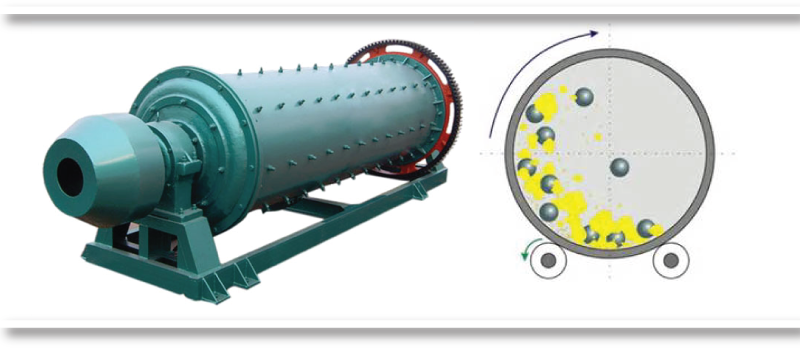

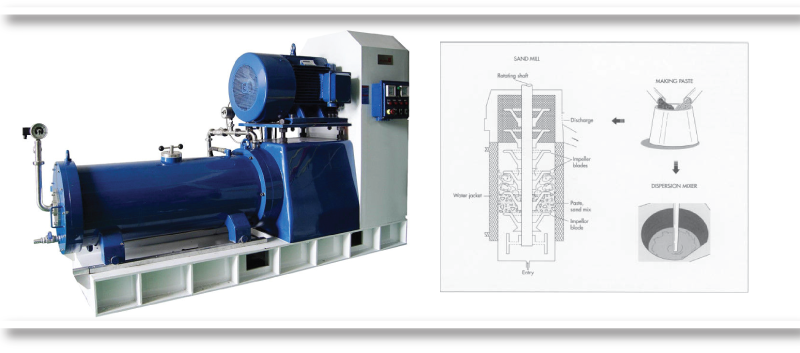

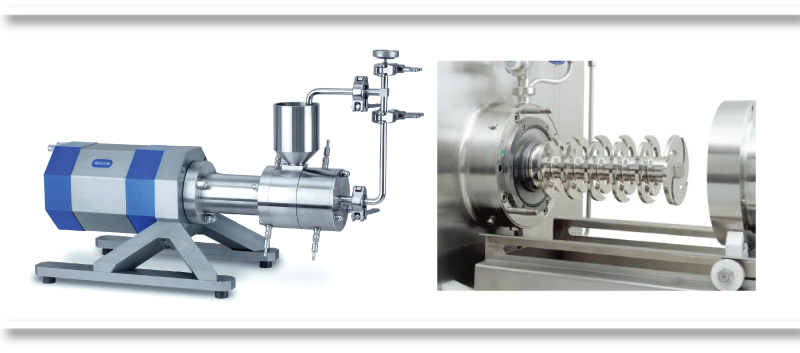

The paint manufacturing industry uses a variety of mills to grind materials. The mills are used to grind solid materials to the desired particle size. The solid materials must meet certain criteria in order to make a smooth consistency and free flowing viscosity of the final product. Roller mills, ball mills, sand mills, and dyno mills are a few examples of commonly used mills. Vertical or horizontal sand mills and dyno mills are the predominate mills used in large commercial production facilities. Below are diagrams showing how all four mills work.

Roller-Mill

Ball-Mill

Sand-Mill

Dyno-Mill

Filters

Filters are used to remove debris from the paint that were introduced during manufacturing. Contaminates may have fallen into the mixers or be particles that were not ground to the correct size. Filters also remove liquid polymers that may not have completely dissolved in the mixers. The types of filters used are single cylinder mills, fine screens, filter presses, centrifugal separators, and settling tanks.