Pigment chillers are used to cool mixers and grinders in the paint and coatings manufacturing industry. There are five industry sectors solvent-based paints, water-based paints, varnishes/clear coat, printing inks, and resins. Each sector is used for specific applications. These range from industrial construction and maritime coatings to home interior and decorative painting. The digest differences come from the additives that create different characteristics in the coatings. The grinders are used to turn raw minerals or synthetic materials into a fine powder. The friction of grinding the raw pigments produces heat which can cause melting. This is counterproductive when a fine powder is the desired result. Producing fine pigment powders on an industrial chiller requires the proper cooling equipment. Whaley Products Incorporated has the ability to design and build the right equipment for any size manufacturing facility.

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

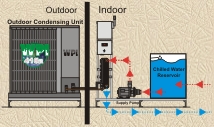

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |